catalyst

A next-gen performance jumping saddle, driven by technology.

read more on Good Grit Magazine

equestrian innovation

Designing for Athletes

Riders and horses are athletes. They frequently suffer pain and injury due to the high-impact nature of the sport. Success as an equestrian depends on a rider’s ability to communicate with their horse. Equipment, especially saddles, can make or break this connection. As a lifelong equestrian, I set out to design a saddle that leverages modern technology for improved comfort and performance.

traditional saddles

Difficult to Manufacture

Requiring specialized artisan craftsmen, today’s saddles are difficult to make and adjust.

Heavy, Outdated Materials

Saddles have been made with the same materials for centuries, and they typically feel heavy and bulky. In the Middle Ages, saddle structures were made of wood and steel, which is how many companies still make them today.

Ineffective Fitting Methods

Saddle fitting today relies on trained representatives, making it costly for the companies and prone to human error. Saddles are typically made in Europe, and the process of getting a saddle custom-made is long and challenging.

impact

Performance, Communication & Comfort

When a saddle doesn’t fit properly, it leads to a cycle of discomfort and miscommunication between horse and rider..

“[Saddle fit] contributes to sourness and other stress. It can affect the quality of the movement and ultimately can affect [the horse’s] interest in jumping.” - Kalli Smith, Pro

In a scientific study by the Journal of Equine Veterinary Science, modified saddles reduced pressures, resulting in greater shoulder and carpal flexion and higher fetlock height during jumps.

crafted for the individual

Technology

Catalyst leverages modern technology to achieve a personalized fit. Using a lidar 3D scanner, each horse is brought into CAD. The curves of the tree and the cushioning are modeled for the specific horse. The same technology can be applied to the rider.

Benefits

Saddle fit is very important for communication and comfort for both horse and rider. This method of fitting saddles offers more precision than current hand-measuring methods.

technology-driven design

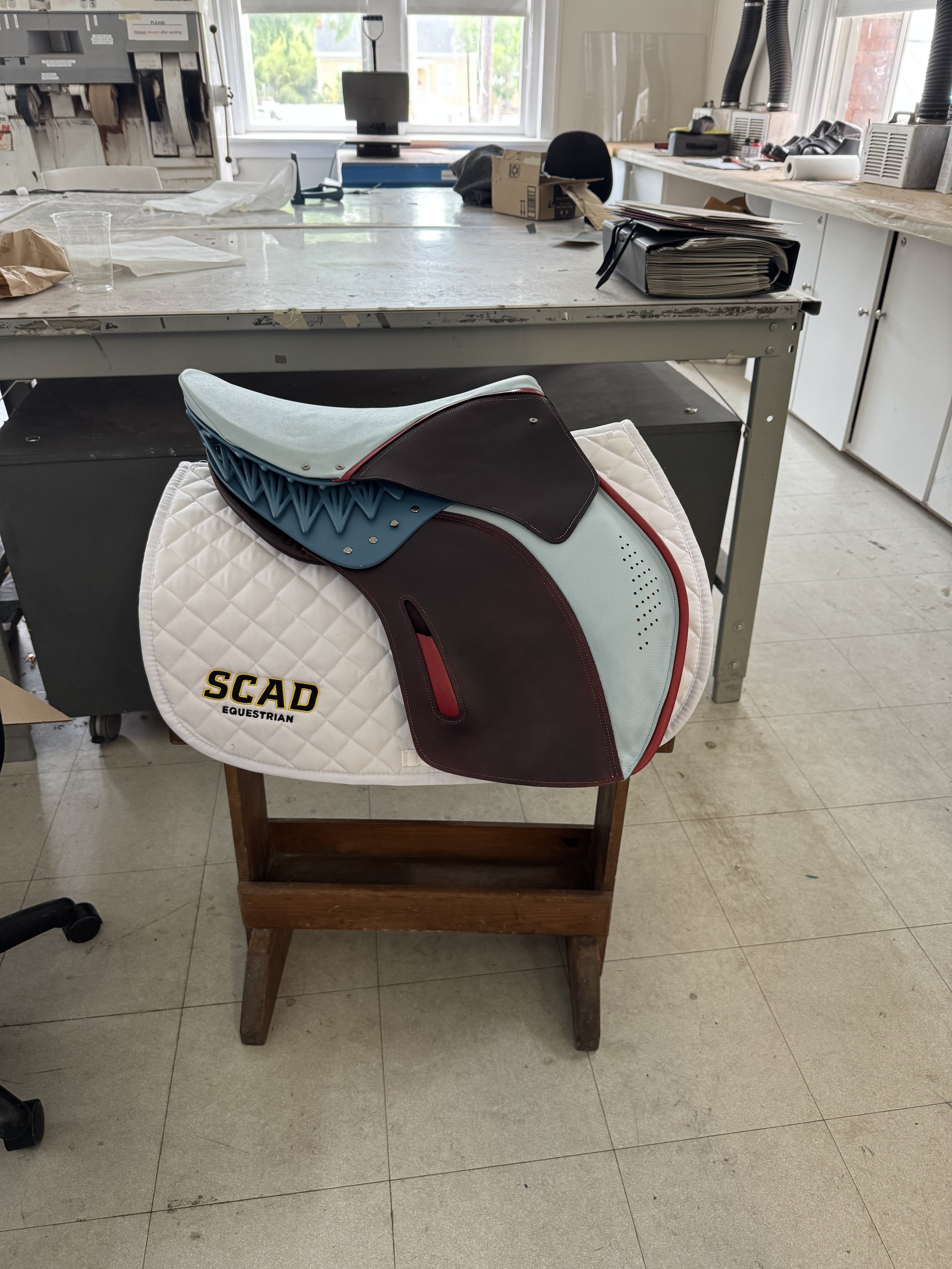

Body

Exposed parametric structure, forward flap and flat seat for jumping

Top Flap

Integrated stirrup bar, perforated leather knee roll, cutout for excess stirrup leather

Bottom Flap

Position supporting leg blocks, two-layer color panel for durability and aesthetics

Saddle Tree

Lightweight, flexible and shock absorbent lattice structure

Angled Panels

Free shoulder movement in jumping

color, material, finish

3D Printed Carbon Fiber

The saddle tree being made of carbon allows for lightweight strength and flexibility.

High Quality Cow Leather

Traditionally used to make saddles, leather is durable and ages beautifully. It is a sustainable material, a byproduct of the beef industry.

Color

Traditional saddles are brown and black, but Catalyst would be made in a range of bold color palettes, such as this soft blue and deep red combination.

a new way to make saddles

Sustainable, Streamlined Manufacturing

Catalyst is made with a minimum of parts, blending traditional craft with new technology. Using rivets rather than synthetic adhesives, Catalyst is sustainable and easily disassembled.

Product Teardown

Product Teardown

Product Teardown

Product Teardown

Product Teardown

Product Teardown

First Iteration Construction

First Iteration Construction

First Iteration Construction

First Iteration Construction

First Iteration Construction

First Iteration Appearance Model

First Iteration Appearance Model

First Iteration Appearance Model

Mock-Ups

Mock-Ups

Tests

Final Saddle Tree 3D Print

Final 3D Prints - Sanding

Final 3D Prints - Sanding

Final 3D Prints - Sanding

Final 3D Prints - Sanding

Final 3D Prints - Priming

Final 3D Prints - Painting

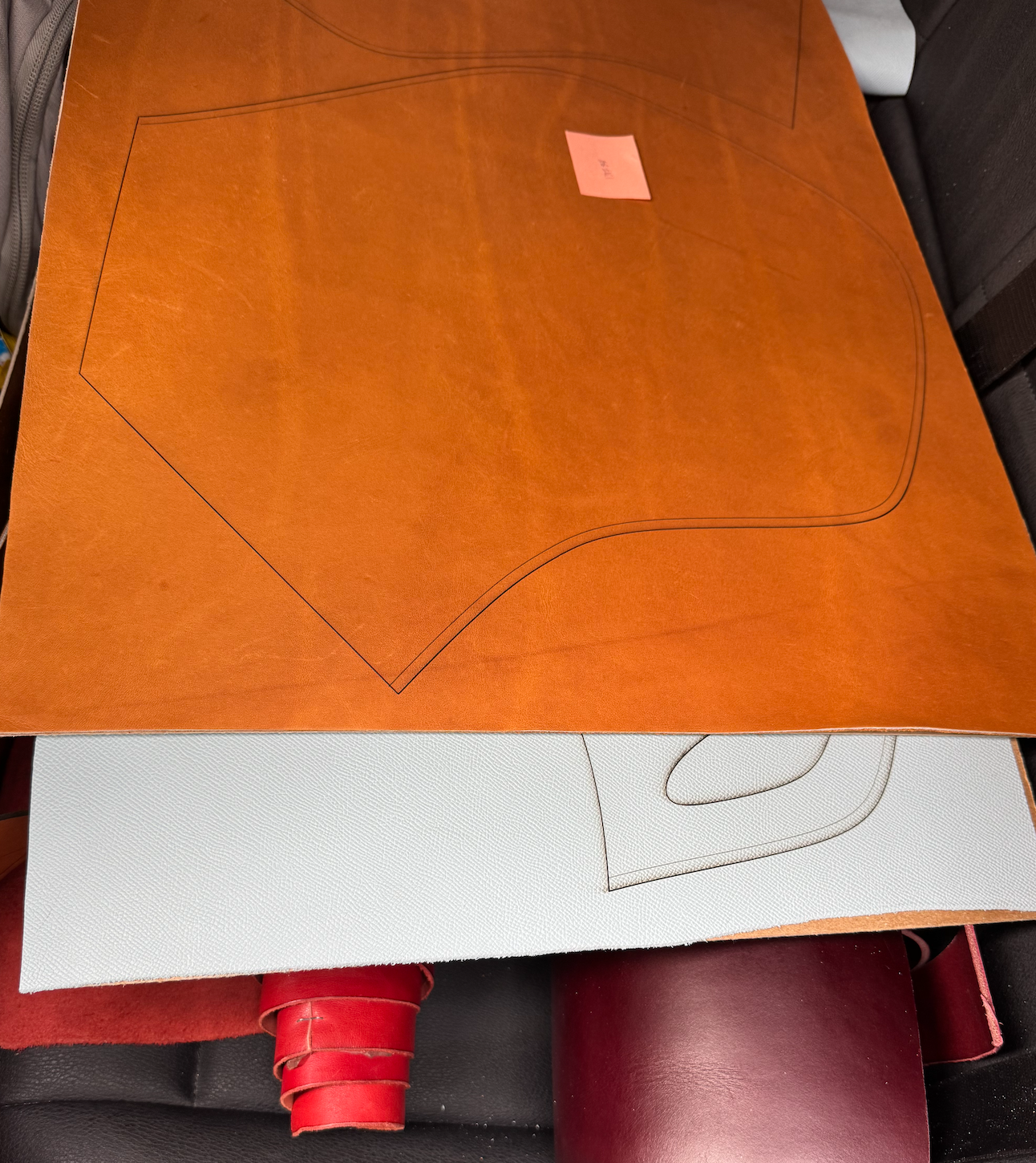

Final Laser Cut

Leather Dying

Final Laser Cut

Final Laser Cut

Final Bottom Flaps

Final Top Flaps

Final Assembled Flaps

Final Assembly Preparation

Final Assembly Preparation

Final Panels

Seat Test

Seat Test

Final Seat

Final Seat

Final Assembly

Final Assembly

Final Assembly

Final Assembly

Final Assembly

Final Appearance Model

leather craftsman

Alexa Chepolis

achepolis1@gmail.com

supporters

Leather Sponsor Tuscan Bull Leathergoods

Professor Paul McGroary

Support SCAD, SCAD Equestrian

media

Studio Photography Sam Murray

Equestrian Photography & Videography Matteo Bariana

Models Belle Cohen & Lexie Kern